When cutting metal, wood, glass and other hard surfaces, it is difficult to imagine lightning that can follow a rotating blade. Traditional rays had difficulties. In other words, the focused laser beam passes through the breeze.

What is laser cutting?

What is laser cutting?

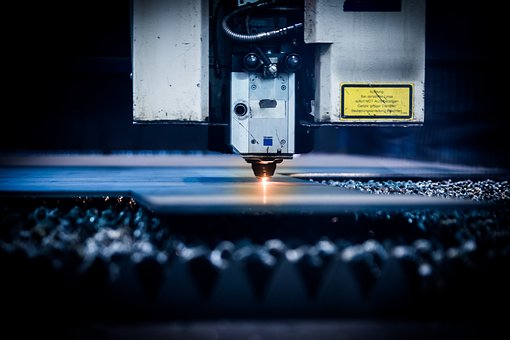

Laser cutting Brisbane is the process of using a laser beam to heat a work piece to the point where the piece is cut accurately. According to Answers.com, the laser machine includes a high-power laser and a computer that directs the laser beam towards the material to be cut. Here the laser beam melts, vaporizes or burns the material along a predetermined cutting line, creating precise and perfectly cut edges.

According to Coherent, concentrates a large amount of energy in a small and clear point. The thermal energy generated by the laser vaporizes a mixture of substances and gases in this small area, or gases such as oxygen, CO2, nitrogen. And/or Helium It is used to expel the vaporized material from the sleeve (the width of the grooves formed by the laser beam); the energy of the beam is applied directly where it is necessary to minimize the area affected by heat beam.

Laser cutting applications

Laser cutting is used by manufacturers, small businesses, schools and fans alike. According to Coherent, typical elements suitable for laser machines include:

Fine non-metallic materials: paper, most plastics, textiles, Mylar stencils, polycarbonates, wood up to 04 inches and thin acrylic can be cut with a laser with an average power of 150 watts (maximum power of 450 watts).

Thick non-metallic materials: to cut thick non-metallic materials, such as thick plastic and wood, up to an inch thick, you need a laser with an average power of 250 to 500 watts (maximum power of up to 1500 watts). In general, low power lasers should work harder to make the same cut. This can reduce the cutting speed and damage excessive heat, chemical changes or heat affected areas.

Metallic materials: Metallic materials generally require high power lasers (150 to 1,000 watts (up to 2500 watts of maximum power)). When oxygen auxiliary gas is used, some thin metals (such as stainless steel or cold-rolled steel) can be cut with a 150-watt laser. Use

Laser cutting is used to cut the desired amount of items of various materials, such as puzzles, clock faces, metal labels, parts and mechanical components, packaging, signs, steel folding Melbourne, patterns, leather sequins, etc.

Advantages of laser cutting

Lasers offer many advantages over other types of cutting. In addition to being able to cut a variety of materials such as paper, plastic, cardboard, leather and metal, the laser is very precise. Once the pattern is programmed into the laser cutter, it is possible to continuously cut an exact copy of the work piece pattern after the work piece. The laser edge is clean. In addition to cutting elements, the laser can cut small and very precise holes with excellent edge quality.

Finally, the cut does not wear the laser beam, which reduces the deformation of the cutting equipment. Lasers have been used for a long time and have proven to be a reliable and advantageous alternative to other cutting methods.